At KIR Ammo, we pride ourselves on our diverse selection of high-quality ammunition. No matter what your shooting needs, we have the ammunition to meet them. A crucial factor to consider when purchasing ammo is the type of cartridge casing. In the world of firearms, the topic of ammunition casings often takes a backseat to discussions about bullet types, gun models, and shooting techniques. However, the humble cartridge casing plays a critical role in the functioning of any firearm, impacting not only the bullet’s performance but also the firearm’s maintenance and longevity.

In this practical guide to ammo casings, we aim to shine a spotlight on this often-overlooked component by dissecting the anatomy of the cartridge casing, exploring its history, and diving into the various types available today. We’ll illustrate these details with diagrams and delve into the manufacturing process of casings. Moreover, we’ll help you understand which casings are best suited to specific use cases, such as hunting, self-defense, competitive shooting, or range practice.

We also added a FAQ at the bottom of the page to address the most common queries around ammunition casings.

As you journey through this guide, you’ll gain a newfound appreciation for the vital role that cartridge casings play in your shooting experience. Regardless of whether you’re a beginner shooter, a seasoned hunter, a competitive marksman, or a firearms enthusiast, understanding cartridge casings will enhance your knowledge and hopefully, your shooting performance.

So, let’s load up and jump into the fascinating world of ammunition casings!

The Fundamentals of Ammunition/Cartridge/Shell Casings:

Before we delve into the intricacies of the ammunition casing, it’s essential to establish a fundamental understanding of what these casings are and the role they play in the grand scheme of firearms. An ammunition casing, also known as a cartridge casing or shell casing, is a container for the components of a round of ammunition. The casing houses the primer, which ignites the gunpowder, and the bullet, which is propelled from the firearm by the energy generated from the ignited gunpowder. In essence, the casing serves as the delivery vehicle for the bullet, allowing it to be fired from the gun.

Casings come in various materials and sizes, each with its unique set of properties that affect the performance and utility of the ammunition. They are a critical part of any cartridge, and their design and construction significantly impact how ammunition functions and performs.

Contrary to popular belief, the casing does more than just hold the bullet and gunpowder. Its base, which houses the primer, withstands the initial explosion when the gun is fired. After the bullet is discharged, the casing also serves a crucial role in extracting and ejecting the spent round from the firearm. This ability to withstand intense pressure and heat, and efficiently eject from the firearm, underscores the importance of quality casing in the reliability and performance of the ammunition.

While the terms “bullet” and “ammunition” are often used interchangeably in casual conversation, it’s important to remember that the bullet is just one part of a piece of ammunition. The casing, primer, and gunpowder are all integral parts of a cartridge, with the casing serving as the foundational structure that holds all these components together.

With this fundamental understanding of what ammunition casings are, we can now delve into the finer details, exploring the different types of casings, how they’re made, and the role they play in the performance of different kinds of ammunition.

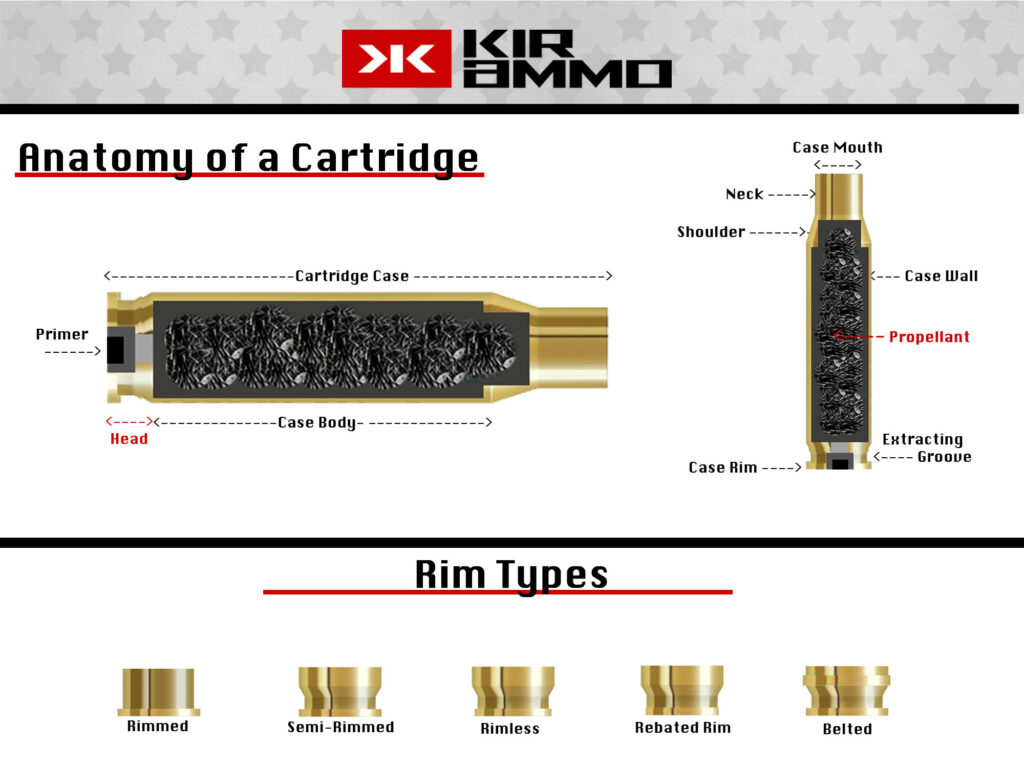

The Anatomy of a Cartridge Casing:

In order to appreciate the full functionality of an ammunition casing, it’s essential to understand its individual components and how they all fit together. A cartridge casing isn’t just a simple container; it’s a precision-engineered component that ensures the correct and safe operation of a firearm. Let’s break down its primary parts:

- Case/Shell:

The main body of the cartridge casing, often simply referred to as the case or shell, is the component that houses the primer, powder, and bullet. It’s typically cylindrical in shape with a slightly conical or ‘bottlenecked’ end where the bullet is seated. The main body is designed to withstand the immense pressure generated when the primer ignites the powder. - Primer:

The primer is a small, sensitive component located in the center or rim of the case base, depending on whether it’s a centerfire or rimfire cartridge. When struck by the firearm’s firing pin, the primer ignites and sends a flame through the flash hole, igniting the propellant powder. In centerfire cartridges, primers are often separately manufactured and then inserted into the case. - Powder:

Also known as the propellant, the powder is held within the main body of the casing. Upon ignition by the primer, the powder burns rapidly and creates a high-pressure gas that propels the bullet down the barrel of the firearm. The type and amount of powder used can significantly affect the bullet’s velocity and, therefore, the cartridge’s performance. - Bullet/Projectile:

The bullet, or projectile, is seated into the open end of the casing. It’s the part that is expelled from the gun and towards the target when the cartridge is fired. Bullets come in a variety of types and sizes, each designed for specific uses. - Rim/Base:

The base of the casing is crucial for the correct operation of the firearm. It is designed to withstand the impact of the firing pin and the pressure of the burning powder. Moreover, the base often features a rim or extractor groove, which enables the firearm’s extractor mechanism to remove the spent casing from the chamber after firing.

Understanding the anatomy of a cartridge casing underscores the complexity behind a component that many may consider basic or even overlook entirely. As we delve into the types of casings, their manufacturing process, and appropriate use cases, remember that each part of a casing is vital to the overall functionality and safety of the ammunition.

Different Types of Cartridge Casings You Might Encounter:

- Aluminum Casings: Lightweight and affordable, aluminum casings are another cost-effective option. Aluminum is a soft metal, so it’s easy on firearms but not recommended to reload.

- Brass Casings: This is the most common type of ammunition casing and is favored for its durability and corrosion resistance. Brass is easy to reload and can often handle multiple uses before wear and tear become significant.

- Steel Casings: Typically less expensive than brass, steel casings offer a more cost-effective option for shooters. However, they are not recommended to reload and also typically not allowed at some ranges due to the risk of sparking.

- Nickel-Plated Brass Casings: These casings combine the durability of brass with the corrosion resistance of nickel. They’re smooth and feed well into the chamber, and they’re easy to see in low light, making them a popular choice for self-defense rounds.

- Berdan-Primed Casings: Unlike the other casing types, which are usually Boxer-primed, Berdan-primed casings have two flash holes instead of one. They’re a bit harder to reload, but are often found in surplus and imported ammunition.

- Polymer-Coated Steel Casings: These casings have a layer of polymer coating to improve performance and reduce wear and tear on the firearm. They offer a cost-effective solution without some of the drawbacks traditionally associated with steel casings.

- Zinc Plated Casings: Zinc is a relatively new entrant in the casing market. Casing aren’t made of zinc, but they are plated with zinc. In addition to corrosion resistance, zinc helps with higher strength of the casing, easier formability, improved recyclability, and cost-cutting measures. Zinc cartridges are typically steel or iron with a zinc coating.

- Rimfire Casings: Rimfire cartridges have the primer compound stored inside the rim of the base. When the firearm’s firing pin strikes the rim of the cartridge, it ignites the primer compound, which in turn ignites the main propellant and fires the bullet.The most common and well-known example of rimfire ammunition is the .22 caliber cartridge, used widely in small game hunting and target shooting due to its low recoil and cost. However, rimfire cartridges are generally limited to lower-pressure calibers, as the case needs to be thin enough for the firing pin to crush and ignite the primer. Due to their construction, rimfire cases cannot be reloaded. Once fired, the crushed rim that contained the primer is permanently deformed.

- Plastic Casings: Centerfire cartridge casings made from plastic have long been considered an elusive yet highly desirable goal. At first glance, plastic appears to be an ideal material for these casings, given affordability, lightweight nature, and water/corrosion resistance. However, several significant challenges accompany the use of plastic in centerfire cartridge cases including inability to secure a primer, limited heat resistance, and lack of strength to withstand feeding and extraction process. Despite these obstacles, ammunition manufacturers have remained undeterred. They have devoted significant resources since the early 1950s to explore the potential of plastics in ammunition-related applications. Perhaps one day materials will advance and this will be come a reality.

Total Polymer Casings:

Polymer-cased ammunition is a recent innovation in the ammunition industry designed to offer an alternative to the traditional brass or steel casings. Polymer, a type of plastic, is used in these casings because of its many potential advantages over traditional materials:

- Weight: Polymer casings are significantly lighter than their brass or steel counterparts. This can reduce the overall weight of the ammunition, making it easier for a soldier or hunter to carry more rounds.

- Cost: Polymer is generally cheaper than brass or steel. Therefore, using polymer for casing can help reduce the manufacturing costs of ammunition, potentially lowering prices for consumers.

- Heat Insulation: Polymer casings do not conduct heat in the same way as brass or steel, and they can help keep a firearm’s chamber cooler. This can be beneficial in situations of rapid or automatic fire.

- Recoil: Some shooters report that polymer-cased ammunition has less perceived recoil compared to traditional ammunition.

However, there are also potential drawbacks to polymer-cased ammunition. For one, the durability and long-term performance of polymer cases are still being researched and tested. The polymer must be able to withstand the pressures and temperatures of firing without deforming or failing. Also, unlike brass, polymer casings cannot be easily reloaded. This may not be a concern for casual shooters, but for serious shooting enthusiasts who enjoy reloading their own rounds, it might be a disadvantage. Lastly, not all guns may function reliably with polymer-cased ammunition. Each firearm is unique, and some might have issues with feeding or extracting these rounds.

How are Ammunition Casings Made?

The process of manufacturing ammunition casings is a testament to precision engineering. Even though they might seem simple in design, the process of creating these essential components is anything but. Let’s break down the steps involved in their production.

- Material Selection and Preparation: The first step in the production of casings is selecting the appropriate material. As we’ve discussed, this could be brass, steel, aluminum, nickel-plated brass, or others, depending on the desired properties of the final product. Once the material is selected, it’s typically cleaned and prepared for the manufacturing process.

- Forming and Shaping Process: The material is then formed into the basic shape of the casing. For brass casings, this process often starts with a small disk of material that’s then drawn and formed through a series of dies to create the cylindrical shape. The neck of the casing, where the bullet is seated, is also formed during this process. The base and rim of the casing are then created.

- Primer Insertion: In the case of centerfire cartridges, the primer pocket is created, and then the primer is inserted into the base of the casing. The primer is a sensitive explosive that’s ignited by the impact of the firing pin, starting the process that fires the bullet.

- Case Filling: Once the casing is formed and the primer is in place, the casing is ready to be filled with powder. The type and quantity of powder used can vary significantly depending on the type of ammunition being produced. Precision is critical in this step; too much or too little powder can cause problems when the ammunition is fired.

- Bullet Seating: With the powder in place, the bullet can be seated into the open end of the casing. The bullet is typically crimped into place, ensuring it remains secure until the ammunition is fired.

- Quality Control and Packaging: The final steps in the manufacturing process involve quality control and packaging. Each round is inspected for defects, ensuring the primer is correctly inserted, the bullet is properly seated, and the casing is correctly formed. Once the ammunition passes quality control, it’s packaged and ready for distribution.

The process of creating ammunition casings is a fascinating blend of precision and engineering. Each step is crucial to ensure the ammunition not only works as expected when fired but also provides the necessary safety measures for the shooter. With this understanding of the manufacturing process, it’s clear that the humble ammunition casing is a marvel of modern engineering. There are slight differences between handgun ammo and rifle ammo when it comes to manufacturing, but the general process is the same.

Selecting the Right Casing for Specific Use Cases

Just as there’s no one-size-fits-all firearm, the same principle applies to ammunition casings. Depending on your shooting needs, certain types of casings might be more suitable than others. Here, we delve into some of the considerations for selecting casings for different scenarios.

- Factors to Consider When Choosing Casings: When selecting casings, it’s important to consider your shooting goals, budget, and firearm type. The casing material can affect the cartridge performance, cost, and the wear and tear on your firearm. Environmental factors, like the desire for recyclability, could also play a role in your decision.

- Casings for Hunting: For hunting purposes, reliability is paramount. As such, brass casings, known for their consistent performance and reliability, are often the preferred choice. Nickel-plated brass can also be a good choice for hunting in damp environments due to its corrosion resistance.

- Casings for Competitive Shooting: In competitive shooting, precision is key, and any misfire or jam can cost valuable points. Here, brass casings are often favored due to their dependable ignition and smooth extraction. However, in high-volume shooting disciplines, steel or aluminum casings can be a cost-effective alternative.

- Casings for Self-Defense: For self-defense situations, you need the most reliable option. Nickel-plated brass casings are often recommended due to their smooth feeding and extraction, along with their corrosion resistance which is important if you carry your firearm daily. We have a great guide on how to choose ammunition for self defense, too!

- Casings for Range Practice: When practicing on the range, cost-effectiveness becomes a significant factor due to the high volume of ammunition used. In such cases, steel or aluminum casings are often the go-to choice due to their lower cost. However, it’s crucial to check whether your firearm can handle these types of casings without excessive wear. Check out our article on affordable options for plinking ammo.

- Casings for Military and Law Enforcement Use: For military and law enforcement use, the emphasis is on reliability, durability, and performance in a wide range of conditions. Brass is commonly used, but steel casings are also chosen for certain applications due to their strength and lower cost.

Understanding the right casing for your specific use case not only ensures a better shooting experience but also aids in maintaining the longevity of your firearm. A well-chosen casing can enhance your performance, whether you’re on the hunt, competing, defending yourself, or simply plinking at the range.

The Evolution of Ammunition Casings

Over the years, ammunition casings have gone through substantial changes to accommodate developments in firearms technology and evolving needs of their users. This evolution has been characterized by innovations in materials used, changes in design, and improvements in manufacturing processes.

- Early Beginnings: The first ammunition casings were made of paper and cloth, used in muzzle-loading firearms in the 16th century. By the 19th century, innovations led to the introduction of metallic casings. These casings were initially made of copper but were quickly replaced by brass due to its superior durability and workability.

- Advent of Centerfire Ammunition: Centerfire ammunition, which has the primer located in the center of the casing base, was developed in the mid-19th century. It represented a significant step forward as it allowed for the development of high-powered ammunition and enabled the casings to be reloaded and reused.

- Development of Modern Materials: In the 20th century, new materials were introduced for casings. Steel, aluminum, and various plastic materials were developed, each with their own benefits and drawbacks. Steel offered durability and lower cost, aluminum provided a lightweight and inexpensive alternative, while plastic allowed for unique applications like specialty shotgun shells.

- Modern Day and Beyond: Today, brass remains the most commonly used material for casings, though steel and aluminum are also widely used, especially for high-volume shooting scenarios. Specialized materials like nickel-plated brass are also prevalent for specific use cases. As we move forward, the quest continues for even more efficient, sustainable, and cost-effective materials for ammunition casings.

The evolution of ammunition casings reflects the continuous innovation and development in the world of firearms. As technology progresses and shooters’ needs become more specialized, we can expect the humble ammunition casing to continue to adapt and evolve.

Frequently Asked Questions About Ammo Casings (FAQs):

Can you reuse ammunition casings?

Yes, certain types of ammunition casings, particularly those made of brass, can be reused or “reloaded”. This involves removing the spent primer, resizing the casing, reinserting a new primer, refilling the casing with powder, and seating a new bullet. Note, however, that not all casings are suitable for reloading, and the process requires specialized knowledge and equipment to be done safely.

What’s the difference between centerfire and rimfire casings?

The difference lies in the location of the primer. In centerfire casings, the primer is located in the center of the casing base. In rimfire casings, the primer is contained within the rim. Centerfire casings are typically used in high-powered firearms and are reloadable, while rimfire casings are generally used for low-powered firearms, like .22 calibers, and are not reloadable. Check out our selection of rimfire ammunition.

Does the material of the casing affect performance?

Yes, the material of the casing can influence several aspects of performance, including reliability, extraction, and the amount of wear on the firearm. Additionally, some materials are more suitable for certain environments. For instance, nickel-plated brass offers better corrosion resistance, making it more suitable for damp environments.

Can you mix different types of casings?

While technically it’s possible to load different types of casings in a firearm, it’s generally not recommended. Different casing materials can behave differently when fired and extracted, which can lead to inconsistent performance and potential malfunctions.

How many times can you reload a casing?

This depends on several factors, including the type of casing, the firearm used, and how much the casing is resized during the reloading process. As a general rule, brass casings can often be reloaded several times, but it’s crucial to inspect them for signs of wear or damage before each reloading.

What causes a casing to crack?

Casing cracks can occur due to several factors, including overuse (too many reloads), excessive pressure during firing, or defects in the casing material. Regularly inspecting casings, especially those being reloaded, is crucial to catch any such issues early on.

Why do some ranges not allow steel casings?

Steel casings can be harder on range equipment, such as backstops and target holders, compared to softer materials like brass or aluminum. Moreover, steel casings are not typically reloadable, which could affect ranges that collect and sell spent casings.

Are steel casings bad for my gun?

While steel casings are generally safe to use, they are often harder on a firearm’s extraction system compared to brass or aluminum. Extended use of steel casings could potentially lead to increased wear on your firearm, so it’s important to monitor your firearm’s condition if you frequently use steel casings.

Can you identify the ammunition type by the casing?

In many cases, yes. Most casings have headstamps – markings on the base of the casing – that indicate the caliber and often the manufacturer. However, the specific type of bullet or load often can’t be determined from the casing alone.

What are nickel-plated brass casings and what are their benefits?

Nickel-plated brass casings are brass casings covered with a thin layer of nickel. The nickel enhances corrosion resistance, making these casings more suitable for humid environments or long-term storage. The slick surface of nickel also aids in smoother feeding and extraction.

Why do some casings have a red or green sealant?

The colored sealant found on some casings is used to waterproof the primer or bullet and prevent moisture ingress, which could compromise the ammunition’s reliability. This is commonly seen on military or surplus ammunition.

What is a Berdan primer, and how does it differ from a Boxer primer?

Berdan and Boxer refer to two different types of primer systems used in ammunition casings. Boxer-primed casings have a single central flash hole and an anvil built into the primer itself, while Berdan-primed casings have two off-center flash holes and an anvil built into the casing. Boxer primers are more common in the U.S. and are easier to reload.

What is case annealing?

Case annealing is a heat treatment process used to soften the neck and shoulder area of the casing to prevent cracking and prolong case life. It’s especially useful for reloaders seeking to maximize the lifespan of their brass casings.

What does “+P” mean on my casing?

“+P” stands for “Plus Pressure”. This indicates that the ammunition has been loaded to a higher internal pressure than standard for that cartridge, resulting in higher velocity and energy. Firearms must be rated for “+P” ammunition to handle the extra pressure safely. Read more about +P and P+ ammunition.

Can a casing tell you anything about the firearm it was fired from?

Yes, certain marks or “signatures” left on the casing can provide clues about the firearm. Marks from the firing pin, extractor, and breechface can be unique to specific firearms, and forensic scientists can often use these marks to link a particular casing to a specific firearm.

In conclusion, ammunition casings are a crucial yet often overlooked component of firearms operation. The materials they’re made from, the processes used to produce them, and their evolution over time, all contribute to how they function in various settings and their impact on overall firearms performance. Understanding these factors and being able to choose the appropriate casing for specific use cases can significantly enhance your shooting experience. Whether you’re a novice shooter, a seasoned hunter, a competitor, or someone interested in the intricacies of firearms, a comprehensive knowledge of ammunition casings adds depth to your understanding of this multifaceted field. Through this guide, we hope to have provided you with a well-rounded insight into the world of ammunition casings.

If you enjoyed this article, please make sure you give us a like on social media, sign up for our e-mail specials, and keep us in mind when you are in the market for a great deal on your favorite brand of ammo! We process orders quickly, we offer free shipping on ammo orders $199+, and we have great customer service. Make sure you check out all ammo we have on sale, too! We look forward to serving you.